What is Predictive Maintenance?

Predictive maintenance involves monitoring equipment condition during normal operation to reduce the likelihood of failures. Unlike preventive maintenance, which is scheduled at regular intervals, predictive maintenance is data-driven and occurs only when necessary, making it cost-effective and efficient.

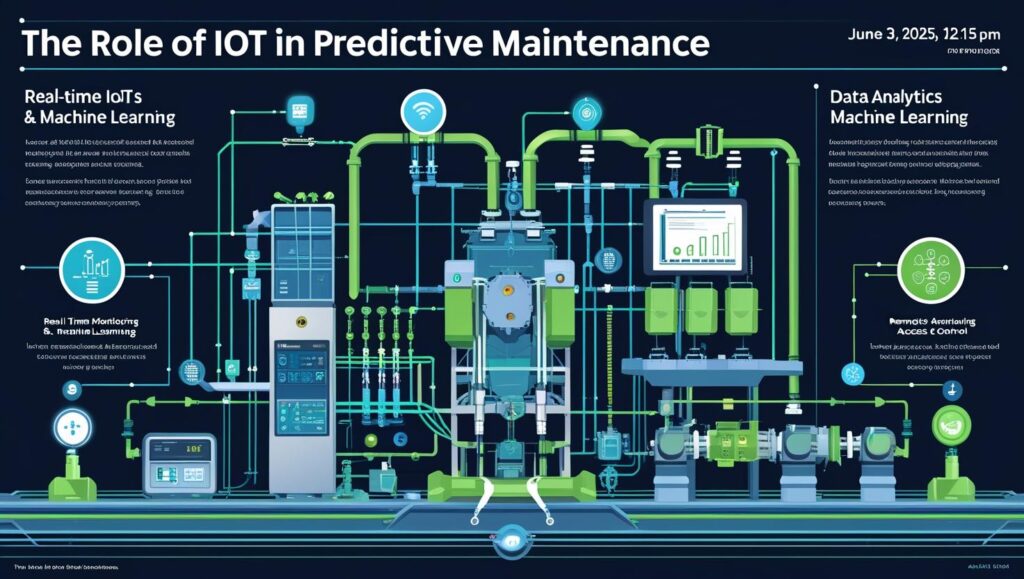

How IoT Enables Predictive Maintenance

IoT plays a crucial role in transforming predictive maintenance from concept to reality. Here’s how:

1. Real-Time Monitoring

IoT sensors collect live data on temperature, vibration, pressure, and more. This real-time monitoring helps detect anomalies instantly, reducing the risk of sudden breakdowns.

2. Data Analytics & Machine Learning

The collected data is processed using analytics tools and machine learning algorithms to predict future failures. This means issues are flagged before they become critical.

3. Remote Access and Control

IoT allows remote diagnostics and control, eliminating the need for constant manual checks. Maintenance teams can act quickly, even from off-site locations.

4. Cost Reduction

By addressing issues before they escalate, businesses save significantly on repair costs, unplanned downtime, and production loss.

5. Improved Asset Lifespan

Continuous monitoring ensures machines operate within optimal parameters, extending their useful life and maximizing return on investment.

Real-World Applications

Industries such as manufacturing, energy, transportation, and healthcare are already leveraging IoT-based predictive maintenance:

- Manufacturing: Reduces unexpected line stoppages.

- Energy Sector: Ensures efficient turbine and grid operations.

- Transportation: Tracks engine wear and optimizes servicing.

- Healthcare: Monitors medical equipment to prevent critical failures.

Challenges and Considerations

While the benefits are compelling, implementing IoT-based predictive maintenance comes with challenges like:

- High initial investment

- Data security concerns

- Integration with legacy systems

- Need for skilled personnel

Partnering with experienced technology providers can help overcome these barriers effectively.

Powered by Webyug Infonet LLP

At Webyug Infonet LLP, we specialize in building IoT-driven solutions that empower businesses to reduce downtime and improve operational efficiency. Let us help you bring smarter maintenance to your operations.

Visit us at Webyug InfonetLLP to learn more.

Conclusion

IoT is reshaping the future of maintenance strategies. With predictive insights, reduced downtime, and improved safety, businesses can stay ahead of the curve. As the industrial IoT landscape grows, predictive maintenance will become a standard practice across all sectors.